MFI SIG 550 / SG-551 Style Front Hooded Sight & Windage Wheel (BLACK ONLY) (NO FIBER OPTIC) Fits SIG USA 556 / Price Includes S&H via 1st Class Mail

SIG-550-HOODED-FR-SIGHT

Limited Supply: only 3 remaining

Was:

$125.00

Sale:

$95.00

Save:

24%

Save:

$30.00

Description

MFI Front Hooded SIG 550/1/2/3 Sight:

Base Price Includes: Windage Wheel, Allan Wrench for Wheel, Fiber Optic & USPS Priority Shipping + Insurance (only if fully optioned / over $100.00 on any order gets you free S&H)

You can save money if you do not want or need either the Windage Wheel and or Fiber Optic (see "Customize Your Item")

This sight lines up ONLY with:

The Non-Hooded Flip Down version that you would see on the SIG SANs 552 Commando has it’s own page:

http://mfiap.com/i-14390350-mfi-sig-sans-556-552-553-front-flip-up-sight-windage-wheel-see-instructions-for-installation.html

The MFI Front Hooded SIG 550/1/2/3 Swiss Style Sight is basically a direct copy of the original except in aluminum. The sight main body and flip up blade are made from 7071 T-6 Aircraft grade aluminum and are precision CNC. I choose aluminum over steel due to the cost effectiveness and versatility of the material. Obviously it would be pointless to make an identical sight to the original & have it be the same price or even more expensive. Additionally 7071 T-6 aluminum can accept a Military Spec. Hard Coat Anodized Finish making it very durable. The cross over windage adjustment wheel / donut and bolt are weapons grade steel and have a Mil. Spec. Black Oxi coating. The Front Sight Fiber Optic Blade that flips up and down is interchangeable with an Original Swiss SANs Flip Up Blade with the Tritium insert. So “Yes” you can swap out the MFI blade for a SIG one if you so choose. Note that like all flip up fiber optic or tritium blades... the MFI blade is taller than the stationary front post / blade. I am not sure why SIG and for that matter everyone on the planet does this… I just choose to follow suit. In our case it does allow more light in and thus makes for a much brighter aiming point. Regardless of your choosing to have the fiber optic or not the flip down blade will come with the sight. The Finish on the MFI Front sight is black only. This is because of the volume we expect to do is 95% black rails. Mil. Spec. Hard Coat Anodizing takes paint very well so if you want yours to be painted... Have at it... Personally I have always had an issue with the heavy coat of paint found on the original Swiss SANs sights (front and rear). Anodizing just looks so much more professional and clean. Front blade is fixed like the originals and I choose the N+ in terms of the original 550/1/2 Sight Heights as it is the tallest and if needed you can file it down. The Front Sight comes with the Windage Adjustment Wheel and Allen Key. For those of you with Optics only weapons or do not currently have a front sight... The installation is a bit tedious... Go to this page for Instructions & Tips on the installation of the front sight. Click on the "Instructions" tab: http://mfiap.com/i-14424650-mfi-sig-sans-556-552-553-front-flip-up-sight-narrow-blade.html

- Original / OEM SWISS SANs 550/1/2 Rear Diopter Sight that has been Welded on the top of the 556 Receiver.

- MFI Rear Diopter & Rail Sight Combination that REPLACES your 556 top rail.

- OEM SWISS SANs 550/1/2 Rear Clip On Diopter Sight that requires modification to the top of the 556 Receiver.

NOTE TO ZEALOUS LEFTIST DEMOCRAT / COMMUNIST ANTI GUN ASSHOLES & THEIR CRONY LAW ENFORCEMENT:

In accordance with the Joe Biden & Beto O’Rourke directive I personally as well my company no longer own(s) or possess any firearms or ammunition. This includes but is not limited to: Handguns, Pistols, Shotguns, Rifles, NFA items, Hog Legs, Fire Sticks, Smoke Poles and or Thunder Clubs.

All firearms that appear on our web site, regardless of what is written about them, are not owned by the company nor possessed by anyone associated with MFI and may even be CGI / PhotoShop. Therefore regardless of any new firearms laws / taxes, no probable cause can EVER be assumed on any property (stationary or mobile) owed by myself or MFI. AGAIN: We are 100% in compliance with any possible new “Biden / O’Rourke Public Safety Act” and therefore NO PROBABLE CAUSE could ever be assumed. Lastly anyone arriving with a warrant of any kind will be assumed to be an IMPOSTER with intent on murdering us and will be treated as such without warning. Those invading our territory may receive serious and even fatal wounds from rusty blades, clubs with bent nails, spear tips, arrows and or crossbow bolts.Instructions

The front sight's dove tail must slide somewhat freely in the dove tail of the gas block.

Meaning: You should NOT have to use a hammer to drift the sight side to side, but it should also NOT be so loose as to slide easily. The right amount of friction is so that the sight drifts sideways via a significant amount of force using your fingers... i.e. nearly all of your might using both hands(tightest) to as easy as half of your strength (loosest). The idea here is that the sight has enough friction in the dove tail not to move during firing.

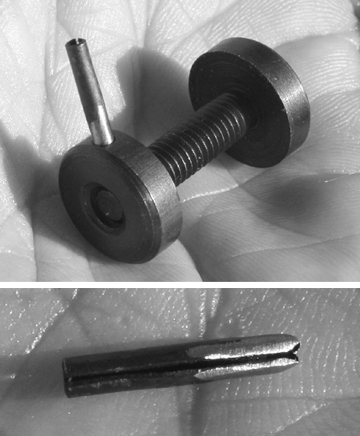

Failure to do this WILL result in the stripping of the cross-over bolt or the shearing of the roll pin inside the donut / round nut.

Hand fitting is required as the dove tails in the gas blocks vary from production to production. Hand fitting can be done via a small hand file used on the slanted edges of the sight's dove tail.

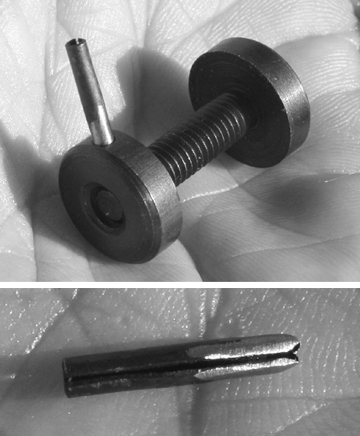

How to install the roll pin in the front sight. It is easy to mess up the roll pin when you first try to install it. Read below to avoid the pitfalls. Not all SIG 556 series weapons come with a front sight installed. So issues like this arise most often when the user is NOT first removing a similar front sight from the weapon and thus is completely unfamiliar with the requirements. There is a first time for everything and that is a part of any weapons system. When SIG installs these at the factory they have a special fixture or a second person to hold the weapon. While a fixture or third person is NOT required it sure makes it a lot easier. All you need is someone to hold the weapon while you hold the punch and hammer. Be sure that the hole in the donut and spline are clean / free of metal shavings. The most common mistake that leads to messing up a roll pin is not having the hole in the spline / adjustment bolt and the hole in the round / donut wheel lined up. You will have to use a punch or something to be absolutely sure of the alignment. Use a 1/16” punch or 1/16” drill bit or 1.5mm allen key… or look around the house and shop for something that fits through both. The number of turns to get the holes lined up is between 2.5 and 3 full rotations (you have to look down the hole). The windage bolt should NOT go past the point of being flush with the outside edge of the donut. It is a lot easier to file or grind down the roll pin at one end and then gently collapse the same end with a vice grips of pliers so that it just fits / sits in the hole of the donut. This will free up one hand. This is almost a requirement.

How to install the roll pin in the front sight. It is easy to mess up the roll pin when you first try to install it. Read below to avoid the pitfalls. Not all SIG 556 series weapons come with a front sight installed. So issues like this arise most often when the user is NOT first removing a similar front sight from the weapon and thus is completely unfamiliar with the requirements. There is a first time for everything and that is a part of any weapons system. When SIG installs these at the factory they have a special fixture or a second person to hold the weapon. While a fixture or third person is NOT required it sure makes it a lot easier. All you need is someone to hold the weapon while you hold the punch and hammer. Be sure that the hole in the donut and spline are clean / free of metal shavings. The most common mistake that leads to messing up a roll pin is not having the hole in the spline / adjustment bolt and the hole in the round / donut wheel lined up. You will have to use a punch or something to be absolutely sure of the alignment. Use a 1/16” punch or 1/16” drill bit or 1.5mm allen key… or look around the house and shop for something that fits through both. The number of turns to get the holes lined up is between 2.5 and 3 full rotations (you have to look down the hole). The windage bolt should NOT go past the point of being flush with the outside edge of the donut. It is a lot easier to file or grind down the roll pin at one end and then gently collapse the same end with a vice grips of pliers so that it just fits / sits in the hole of the donut. This will free up one hand. This is almost a requirement.

Details

- SIG-550-HOODED-FR-SIGHT

- SIG-550-HOODED-FR-SIGHT

- MFI

- Available

- New

Shipping Information

- Item Requires Shipping

- 0.1 lbs.

-

SHIPPING IS INCLUDED VIA USPS on orders over $82.00 Dollars AND OR If S&H is INCLUDED in the Title / Discription.

Customer Reviews

Total Reviews (0)

Total Reviews (0)

You must login to post a review.

Write the First Review!